When is it Time to Retire Your Ladder?

The average ladder goes through different phases in its lifespan. However normal this process may be, it is important to be mindful of your ladder’s stability, and not let complacency keep you from retiring a ladder that has had too much wear and tear.

SIGNS OF A WEAKENED LADDER

If you’re a pro, you’ve likely seen weakened and damaged ladders before, and may have had to dispose of them, too; but if you’re more of a DIY consumer, you may not have. Whether you’re a pro or DIYer, here are a few things to be mindful of when checking your ladder.

FIBERGLASS BLOOM

Fiberglass ladders are a game-changer for electricians and other pros who work around electrical materials. Their non-conductive rails make work safer, which is always the top priority. When properly cared for, your fiberglass ladder can last a long time; alternately, heavy or poor use can shorten its lifespan. Before stepping onto your ladder, you should always check it for signs of damage, including fiberglass bloom.

You’ve probably seen it before- maybe on your own ladder or maybe just on an old fiberglass surface. Fiberglass bloom occurs when the small fibers in the fiberglass become exposed to the sun or heat, or just heavy use in general. The small fibers bloom out and when touched with bare skin, can cause pain, itchiness or discomfort.

Fiberglass bloom isn’t just problematic for giving you splinters; it’s also problematic because a fiberglass ladder with fiber bloom can become conductive when wet. Obviously, this is a major concern for the safety of those working around electricity. If you work around electricity and have a ladder with fiberglass bloom, it is time to remove that ladder from service.

CRACKS

Another concern when dealing with a fiberglass ladder, is cracking. While aluminum ladders are prone to dents, fiberglass ladders on the other hand, can crack, usually as a result of impact. Prevent cracks by not throwing your ladder out of a truck or letting it fall. If, upon examination, you see that your ladder rails have cracked, remove it from service.

DEFORMED/DENTED RAILS

Although there are many parts of a ladder that can be replaced, like the rungs, there are other parts that cannot, and that includes the rails of your ladder. If your ladder’s rails are dented, cracked, or deformed, it threatens the structural integrity of the ladder, making it unsafe to use. Dented, bent, deformed ladder rails are dangerous, and need to be removed from service as soon as possible.

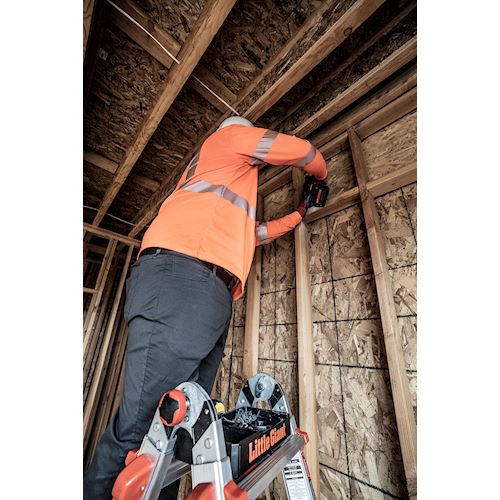

WORN TREAD

The treads on your ladder are important. Now, you may be wondering, where are the treads? Typically, your ladder has treads on the rungs and feet, and if either the rung treads or feet treads have been worn down too much, they should be replaced. Although the process can be tedious, taking the time to have those parts replaced on the ladder will keep you safe while you work.

NEXT STEPS

If you’re at a job site and see that your ladder needs to be retired/removed from service, your next steps are simple. Stop use of the ladder, notify your supervisor, and tag it, so no one uses the ladder that has been determined unsafe for use. If you are a DIY consumer, the process can be a little more difficult. By simply throwing the ladder away or taking it to a landfill, you run the risk of someone taking the ladder and using it anyway, despite it being unsafe. It is important to take a ladder that has been damaged and destroy it by cutting the rungs or dismantling it in other ways. If you have the ability to destroy a ladder, making it unusable, do so. If you don’t have those resources available to you, reach out to a local business to see if they can assist you.